Searle's apparatus simulator

Explore elasticity interactively: Dive into the physics of elasticity and discover how Young's modulus of a material is experimentally determined.

Searle's apparatus

Elasticity plays a key role in materials, from everyday objects to advanced engineering. Ever wondered how load affects extension? Step into the world of material properties with our interactive Searle’s Apparatus Simulator. Adjust the load, experiment with different materials, and see how stress and strain interact in real time. Uncover the principles of elasticity—start your exploration today!

\( Y = \frac{4 \cdot M \cdot g \cdot L}{\pi \cdot d^4 \cdot \Delta L}

\)

Mathematical description

where:

- \( Y \) is the Young’s Modulus of the material

- \( M \) is the mass applied to the wire (load)

- \( g \) is the acceleration due to gravity (9.8 m/s²)

- \( L \) is the original length of the wire

- \( d \) is the diameter of the wire

- \( \Delta L \) is the extension of the wire due to the applied load

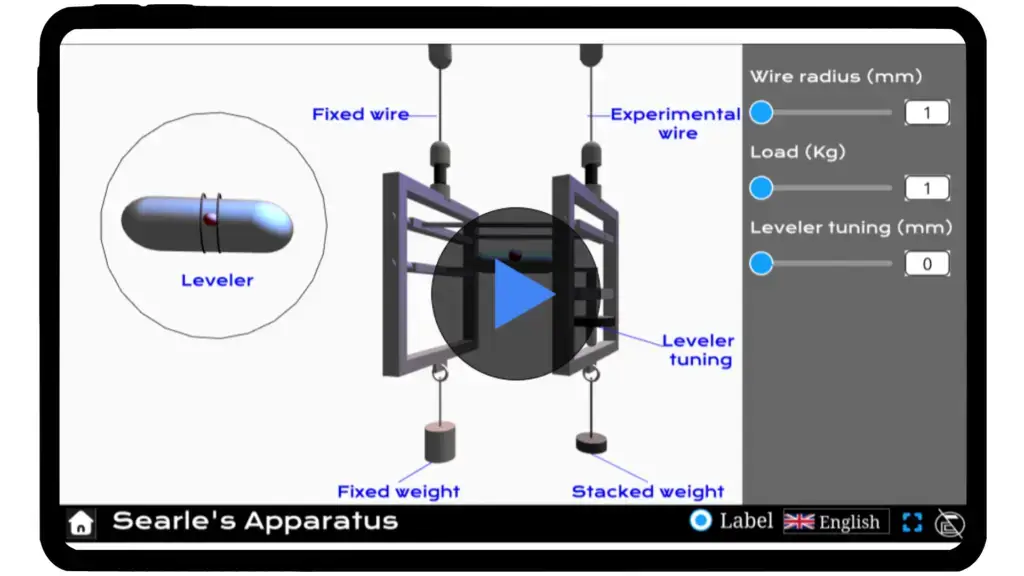

Tutorial video

Take a quick spin through our simulator!

Simulator

Discover how Young’s Modulus is calculated with our interactive Searle’s Apparatus Simulator!

Adjust the wire radius and applied load to explore the precise tuning required to keep the ball perfectly leveled in the spirit level.

Interactive Physics Simulator – Searle's Apparatus

🌟 You May Also Like

Suggested experiments and activities based on your progress...